Revolutionize

Discover the power of high-powered lasers up to 3000 watts.

Currently being used on applications ranging from:

Maintenance shut downs

Graffiti removal

Surface cleaning and profiling prior to coating applications

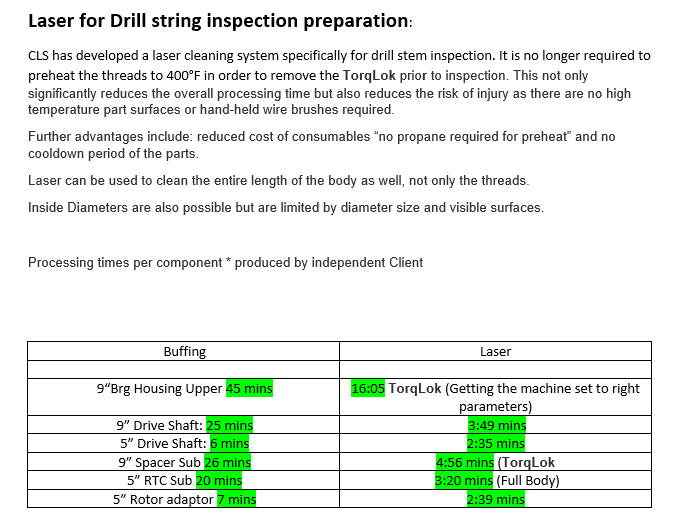

Drill stem inspection (directional drilling)

Fire and flood restoration

Advantages of Laser Cleaning for Weld Preparation

Laser cleaning offers numerous benefits for weld preparation and cleaning. It is a non-contact process that ensures no damage to the base material. The precision of laser cleaning allows for targeted removal of contaminants, resulting in cleaner welds and improved weld quality. Additionally, it is an environmentally friendly solution, eliminating the need for chemical cleaners and reducing waste.

Key Advantages

- Non-contact process

- Precision cleaning

- Environmentally friendly

- Improved weld quality